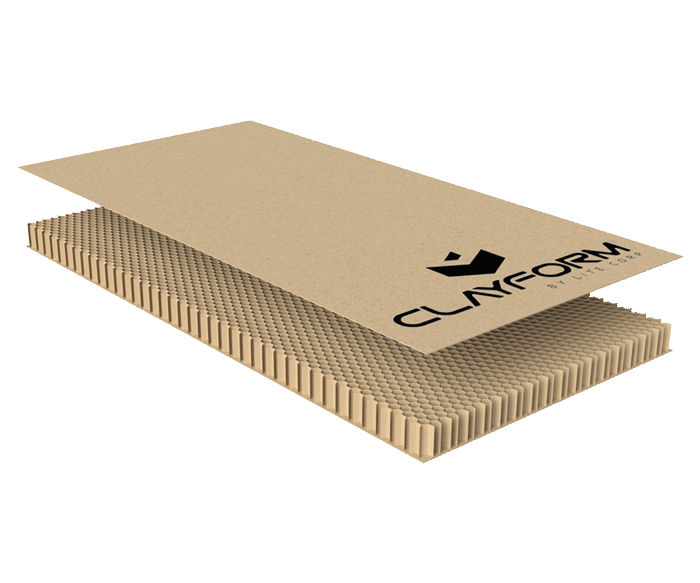

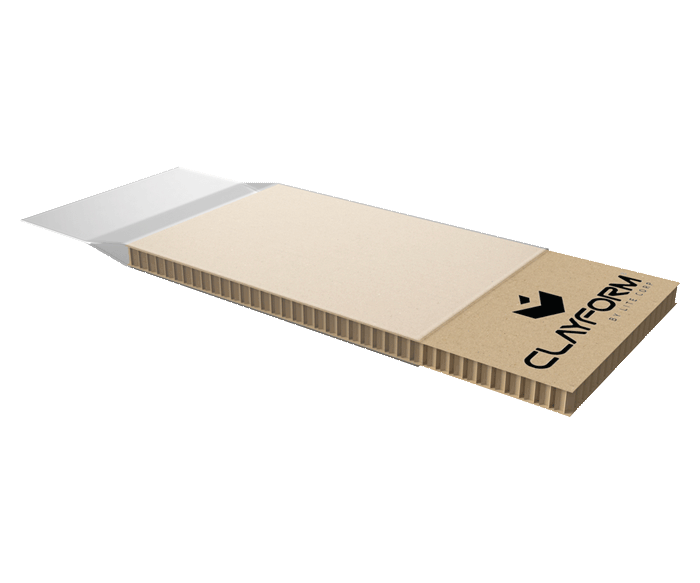

Honeycomb Cardboard Voidformer

Clayform is the premiere construction voidformer solution for engineers and builders across Australia.

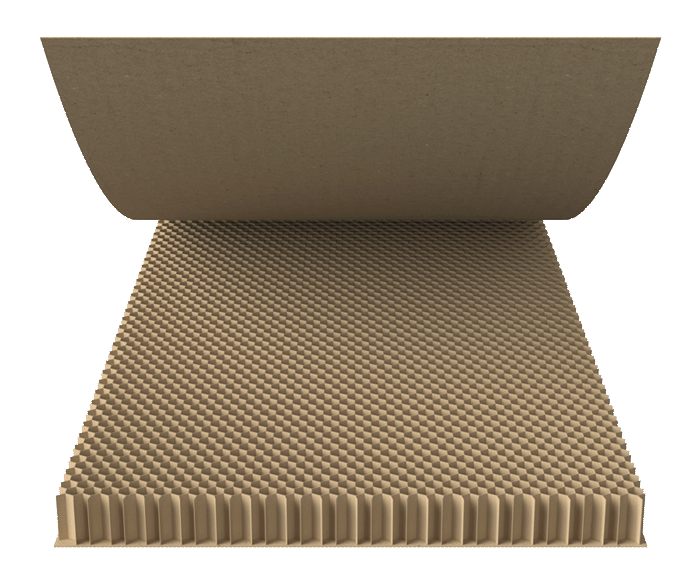

Environmentally-friendly paper honeycomb cardboard is built for purpose: light, strong and results in substantial cost savings for your construction projects.

Australian Made

Superb strength to weight ratio

Suited for reactive soils

Environmentally Friendly

100% Recyclable

Fast Delivery

Why use a voidformer?

Reactive soils occur extensively across Australia.

These soils typically contain a higher proportion of clay and can expand or contract when impacted by high moisture levels. The reactivity level of soil is generally detected in the pre construction phase of a building project via a geo technical analysis. A common solution to prevent the potential for issues caused by ‘expansive’ soils is to install a sacrificial or collapsible ‘void former’ product between the ground and concrete, providing room for the soil to expand should it need to in the future.

THE SOLUTION: CLAYFORM HONEYCOMB CARDBOARD VOIDFORMER

STRONG FOR THE JOB — WHILE BEING ECO-FRIENDLY

Our Clayform void filler panels are supplied in various standard thicknesses from 20mm to 200mm. Thicker panels can be produced when required. Our Clayform void former range is produced using 100% recyclable paper and can be supplied to site in bags to provide additional protection from the elements.

Choose Our Void Former Solution Today

Protect your structure from the effects of ground heave with our innovative void-forming solutions. Australian-made, lightweight handling yet offering strong support prior to concrete pouring, Clayform solutions are available nationwide with generally fast delivery timeframes from order placement. We also provide a comprehensive specification guide for your reference.

PROJECTS

The Ribbon, Sydney

Location: Sydney CBD

Quantity: 1,280 m2

Phillip Island Visitor Centre, VIC

Location: Newhaven VIC

Quantity: 4,500 m2

FAQs

Not typically. Styrene is generally used as a void former on residential slabs in the ‘waffle pod’ system. The paper honeycomb cardboard is used in areas of highly reactive soil where waffle pods are not suitable as they do not provide sufficient ‘give’. The paper honeycomb cardboard is used as an alternative to styrene where an environmentally-friendly alternative is needed.

Suspended slab on ground or suspended slab on grade.

- Fully-suspending the slab on piers and metal decking.

- Removing fill from site and importing less reactive fill.

- Deep stiffened raft slab.

Building projects are typically designed to drain to prevent water ponding under concrete. If a project is designed correctly with drainage there will be no ponding where the void is.

Honeycomb void formers will collapse if they receive heavy rain or are exposed for an extended period of time. As per our install guide, we recommend installing the product and pouring concrete as soon as possible following install.

- Coordinate delivery to site so the sheets can be installed as soon as possible. Lite Corp work with reliable freight carriers to ensure timely delivery

- Ensure a well-drained site (e.g. by use of appropriate subgrades).

- Select the individually-bagged option for additional moisture protection.

- Install a blinding layer immediately after installation for particularly wet areas.

- Protect and store the product well prior to installation.

Following are some appropriate subgrades, with 20mm aggregate or smaller:

- Natural surface

- Pea gravel

- Crushed rock

- Crushed recycled concrete

Yes. We use only FSC-certified paper, with 85% recycled material used in the product. It is fully recyclable.

No. Individually-bagged void former will provide temporary protection against weather, however we recommend pouring concrete maximum 3-5 days following installation – and preferably earlier.

On dry sites where rain is not predicted, and the product can be installed and concrete poured within 1-2 days.

Yes, Clayform is manufactured locally by Lite Corp, a family-owned company.

There are several standards relevant to the suspended slab on ground; AS2870-2011 Residential Slabs and Footings contains a range of reactivity classifications, from ‘A’ (little or no ground movement) through to ‘E’ (extreme ground movement from moisture changes). Void former is generally an option for classes H1, H2, E and P. Several further standards then come into play: AS3600:2018 (Concrete Structures, Steel & Tendons), AS1170 (Structural Design Actions), AS2159:2009 (Piling) and AS4671:2001 (Steel reinforcing materials). Each standard must be considered when designing the suspended slab on ground.

Paper honeycomb cardboard void formers are not termite-prone. Following installation they are typically covered with concrete in 3-5 days. They are intended as a temporary formwork while a building is constructed and will degrade through ground moisture over time.

Our commitment to sustainability

Our vision is to produce a range of sustainable honeycomb cardboard products that help businesses in various industries meet and exceed their environmental impact reduction goals. Our success is driven by our commitment to innovative excellence in manufacturing and a comprehensive research and development (R&D) program.

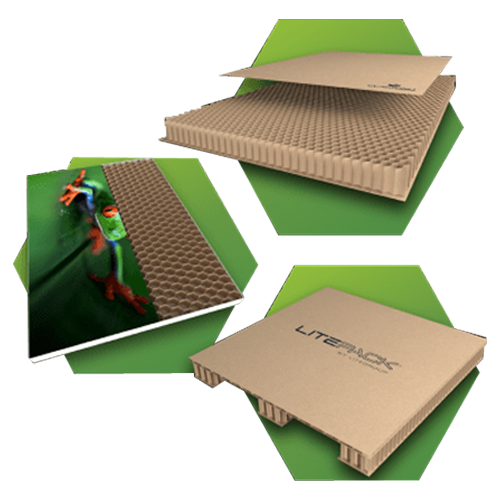

Honeycomb cardboard is 100% recyclable and suits the green credentials of businesses without compromising cost or function, while also appealing to consumers. No fuss, no wastage or costly replacements, just strong and safely disposable material.

Our commitment to sustainability

Our vision is to produce a range of sustainable paper honeycomb cardboard products that help businesses in various industries meet and exceed their environmental impact reduction goals. Our success is driven by our commitment to innovative excellence in manufacturing and a comprehensive research and development (R&D) program.

Paper honeycomb cardboard is 100% recyclable and appeals to our end user consumers as well as our business partners seeking eco friendly material replacements for their supply chains.

About Lite Corp

Lite Corp is the leading honeycomb cardboard manufacturer in Australia.

We have been manufacturing a range of innovative honeycomb cardboard products locally in Australia since 2015. Having successfully launched our void filler line for the construction industry, we have now expanded our range to include innovative packaging solutions through to premium printable graphic board products.

Lite Corp delivers manufacturing excellence, a commitment to sustainability, and excellent customer service.

About Lite Corp

Lite Corp is the leading paper honeycomb cardboard manufacturer in Australia.

We have been manufacturing a range of innovative paper honeycomb cardboard products locally in Australia since 2015. Having first successfully launched our void filler line for the construction industry - Clayform, we have now expanded our range to include innovative packaging solutions all the way through to premium printable graphic board products.

Lite Corp delivers manufacturing excellence, a commitment to sustainability, and excellent customer service.