Businesses that create display boards often use products that feature polystyrene foam. This is bad news for the environment, since foam isn’t biodegradable or sustainable. Here’s an alternative: honeycomb cardboard is 100% recyclable, economical, durable and lightweight.

Display boards are a popular form of advertising for businesses of all sizes – effectively pulling the attention of people walking past.

Polystyrene foam has traditionally been used as the mounting material, sandwiched between two pieces of cardboard. Although foam boards are long-lasting, affordable and lightweight, there are serious environmental concerns.

The environmental problem with polystyrene foam:

It isn’t biodegradable: As a form of plastic, it remains in the environment for thousands of years, when thrown away as litter.

It cannot be easily recycled: Council recycling doesn’t accept polystyrene, it needs to go to designated facilities.

The manufacturing process is energy-intensive and uses petroleum, a non-renewable resource that’s highly polluting.

Fortunately, many retailers are now looking for alternatives to foam boards, as the tide turns towards greener business practises and individuals try to minimise their ecological footprint.

It turns out that consumers are increasingly drawn to organisations that embrace corporate sustainability, according to a survey by research firm Nielsen:

“A whopping 81% of global respondents feel strongly that companies should help improve the environment.”

What if printers and design agencies could attract customers who care about the environment, by creating premium display boards that are 100% recyclable and economical – with all the benefits of traditional foam?

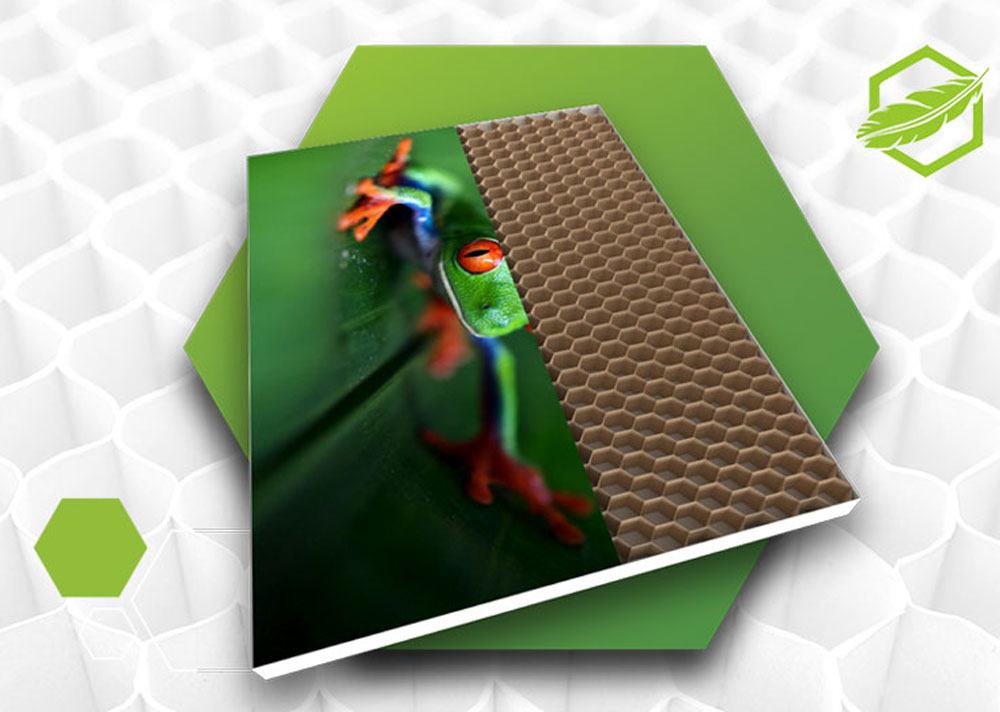

Introducing honeycomb cardboard for sustainable printing materials…

What is honeycomb cardboard?

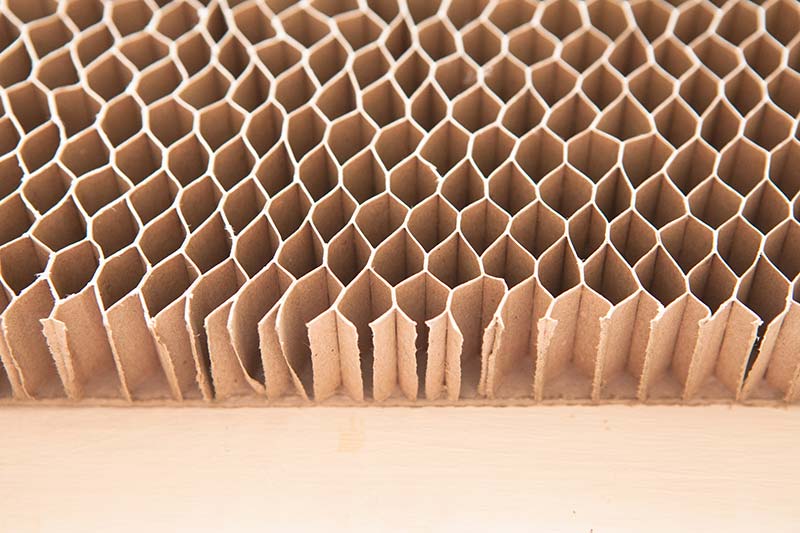

Honeycomb cardboard consists of sheets of Kraft paper that are shaped into hexagonal cells and glued together to form a rigid board. This material is sandwiched between two thin layers of paper or cardboard, to create a robust structure.

Placing the honeycomb core between two layers produces high tensile strength.

Many people find this surprising, but this layout enables the honeycomb cardboard panels to operate like a steel l-beam that’s frequently used to carry heavy loads in construction – with the added benefit of being extremely light.

A lesson from bees…

Think of an actual honeycomb that bees build to store their honey, pollen and larvae.

Honeycomb sheets look very much like that – serving as another classic example of nature inspiring design.

Unsurprisingly, nature knows best when it comes to architecture.

There’s no accident behind the hexagonal pattern of natural honeycomb – bees build their homes in this shape because it helps them to efficiently create honey and communicate with each other.

Why do humans mimic this particular pattern for printing, packaging and building materials?

The combination of hexagonal cells leaves no gaps. Although other shapes like triangles and squares share this quality when merged together, hexagons are superior because they require the lowest volume of materials to build a structure (wax for honeybees and paper for sustainable printing solutions).

In other words, this unique geometry creates a low density and high-strength structure that uses the least amount of material.

The benefits of honeyboard cardboard for the printboard and design industry:

- 100% recyclable (easy to do through kerbside recycling)

- Completely degradable

- Economical

- Lightweight

- Eco-friendly signage is easy to assemble, dismantle and transport

- Extremely strong with a high compressive strength: withstanding heavy loads

- Stunning print quality when coupled with Kraft or white facing

- The board can easily be shaped, cut and customised

- Available in many sizes

- Easily machinable

- No fuss or wastage

- No ISPM15 requirement for export purposes

There are many uses for honeycomb cardboard sustainable printing materials:

- POS signage

- POP displays

- Portable display boards

- Shop fittings

- Exhibition graphics

- Mounting board

- Digital printing

- Wide-format screen printing

- Semi-permanent or permanent installations

A high density honeycomb core can also be used to create more rigid structures for display:

- Pin boards

- Divider walls

- Partition panels

- Whiteboard underlay

- Hoarding systems

- Lightweight decorative beams

- Acoustic systems

Lite Group honeycomb cardboard manufacturers– Made in Australia:

As a leading manufacturer of printable graphic board products, our mission is to help customers to meet and exceed their environmental impact reduction goals. We’ve been doing this since 2015 and never compromise on quality. Our team always strives for excellence in manufacturing, research and design.

We’re an Australian company, so all of our products are made here. We use fast national delivery to reach our customers in a timely manner.

If you want to find out more about our honeycomb cardboard printboards and display products, please contact us on or call 1300 955 002.